Beyond LLMs: Valuable Use Cases for AI in Engineering Design

AI/ML in core engineering disciplines (aerospace, mechanical, chemical, …) -- where you should be focused (especially if you are a student or assuming AI will affect your career)

With an abundance of “AI can do ___” headlines constantly circulating over the last ~3 years, how much of that have you seen dedicated to the engineering industries? After all, these disciplines (like aerospace, chemical, and mechanical engineering) produce essentially all the things around us; the cars we trust to safely get us from A to B, the planes we fly at 600mph in with our families, the electronic devices that are a part of our daily rituals, and the marine industry that brings us our (too frequent) Amazon packages, to name just a few.

So, with such a burden of responsibility to ensure safety, and yet with a natural yearning to innovate and advance technology by adopting new tools like Artificial Intelligence (AI) and Machine Learning (ML), the engineering disciplines have a unique pathway for validating and adopting AI technologies compared to most. After all, a mistake at a powerplant due to a faulty AI-based recommendation (e.g. a false maintenance shutdown recommendation, where even 12 hours of down time represents a cost millions of dollars) is a lot less forgiving than a strange friend recommendation on Instagram.

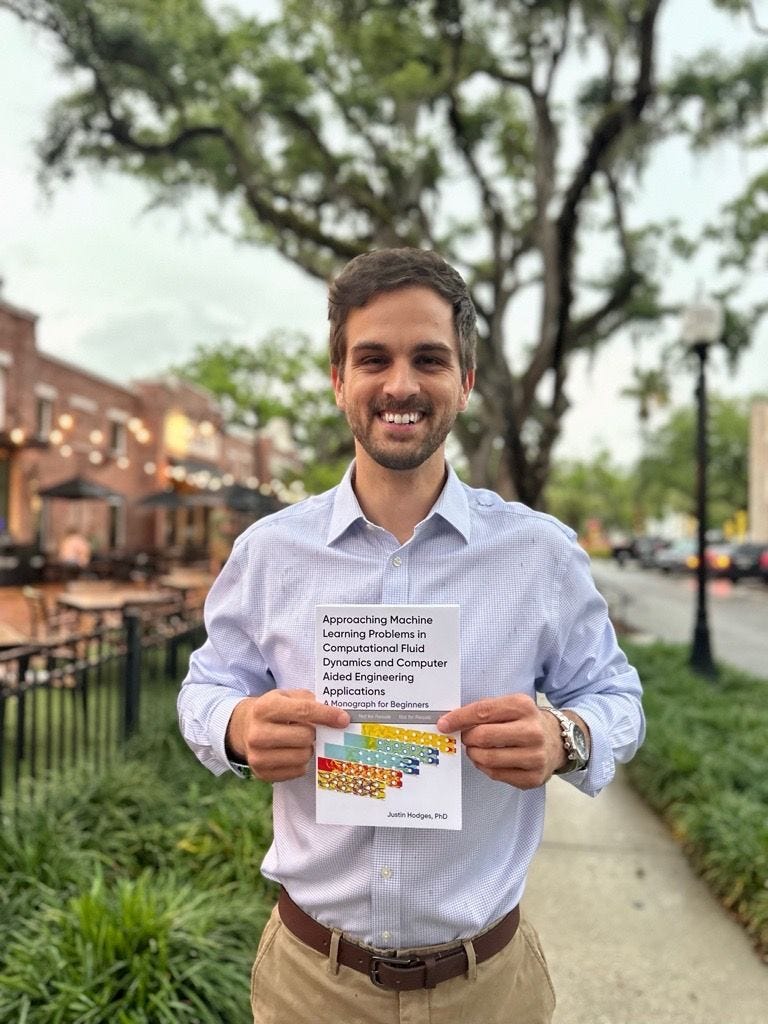

I’d like to introduce the author of this guest post now - Dr. Justin Hodges from ‘ AI/ML in Engineering, Physics, Aerodynamics’, and author of a book on the same topic. In this blog, Justin strives to form a high-level and gentle introduction to these valuable use cases for AI in the engineering design teams (one digestible for folks who aren’t expert in the engineering disciplines specifically).

For the next three days, we’re teaming up: subscribers get 30% off both newsletters.

Perhaps a good place to start is generally how things are done today (the environment AI methods are being brought into).

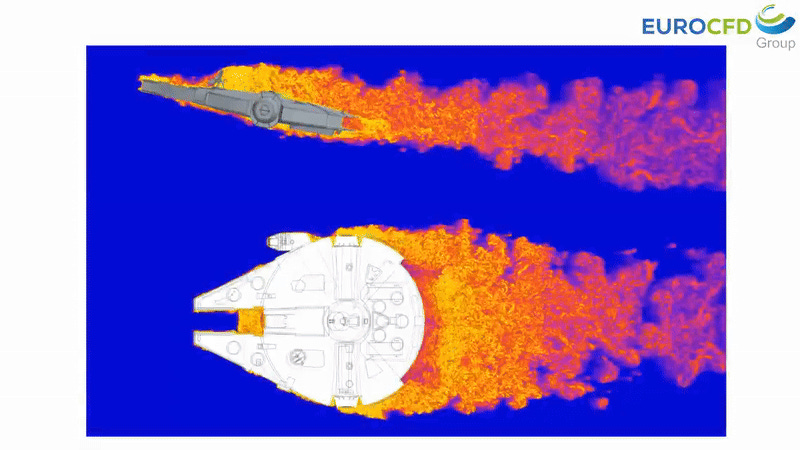

In the days of old, engineers built with slide rules in hand and trial-and-error as their compass. Progress was etched by the slow grind of physical prototypes—wind tunnels, test rigs, and bench trials. Insight came at the cost of time, material, and sometimes failure. As you can imagine, with the ever-increasing availability of impressive computer hardware resources, we have a new way of doing things that includes quite a lot of computer calculations. More precisely, these ‘computer calculations’ are numerical methods that strive to simulate how our designed products (e.g., an aircraft engine) would perform while in operation in the real world. For example, computer simulations that can answer questions like ‘how thin can I make this car suspension system without shortening the life (fatigue life, crack forming, etc.’, or ‘how should I design the car’s underbody so that it minimizes drag for better fuel efficiency and lower emissions’.

I say ‘strive’ because, depending on the physical phenomena you are modeling, these numerical methods can either provide you with an exact solution, or, in other cases, simply do their best to approximate and guess the real behavior (spoiler alert: often, it is the latter). For example, the phenomenon of heat conduction in solid bodies is relevant for many engineering designers, and (depending on the problem) can be quite well understood and treated linearly (Fourier’s law of heat conduction). However, when we have fast-moving fluids around our cars, boats, airplanes, etc., we can have turbulent flow that makes our job remarkably more challenging. Unlike heat conduction, this is a real headache for us to understand, whereby we have more unknowns than equations and (literally) have made up ‘approximate enough’ equations so that we can close our numerical schemes to get reasonable estimates.

“Turbulence is also the primary cause of viscous drag with 30% of the energy consumption worldwide being spent on overcoming drag in transportation” [1]

Yes, you read that right — 30% of energy consumption worldwide originates from managing these flow-fields in our transportation (cars, ships, planes, …). Even as someone with a PhD and nearing 10 years of experience in industry, that figure staggers me and makes me double-take. You can read the full Key World Energy Statistics report cited here [2]. This idea of reducing energy consumption (and also C02 emissions) is one example that can make almost anybody appreciate the need to better understand turbulent flow.

Anyway, before I get tunnel vision talking about aerodynamics, I simply hope to have set the stage of the current paradigm in engineering design — we combine physical measurement with simulation/numerical methods to pragmatically design and validate our engineering designs before we manufacture them. This is the ‘bone marrow’ of engineering today — Digital Twins. A vertebra that spans all engineering teams and phases of the product lifecycle, which is a digital representation of anything we want to design and fabricate. This digital representation allows us to tune and tweak things about our design, and then rapidly check the results we could expect (much faster than if we physically tested everything). A Digital Twin, just to be clear, is not merely a model. It is a living digital reflection of a physical object, system, or process. It mirrors its real-world counterpart in structure, behavior, and function—often in real time—drawing breath, as it were, from data, sensors, and computational power.